Conveyor belts are among the most important mechanical handling systems used in factories and industrial facilities. Machine Belt Technology offers integrated solutions for the design and installation of conveyor belts, ensuring the continuous and smooth flow of materials and products from one point to another, reducing the need for manual labor and increasing production efficiency.

These systems are used in various sectors, such as mining, the food industry, the cement industry, ports, and airports. The importance of the conveyor belt lies in its ability to achieve a consistent flow of materials, reduce operating costs, and enhance safety standards within the workplace.

Types of Conveyor Belts and Their Uses

Conveyor belts vary depending on the nature of the materials being transported and operating conditions. Machine Belt Technology offers consultations to select the optimal type for each application. The most prominent types include:

Rubber belts: Suitable for transporting heavy materials such as coal and gravel.

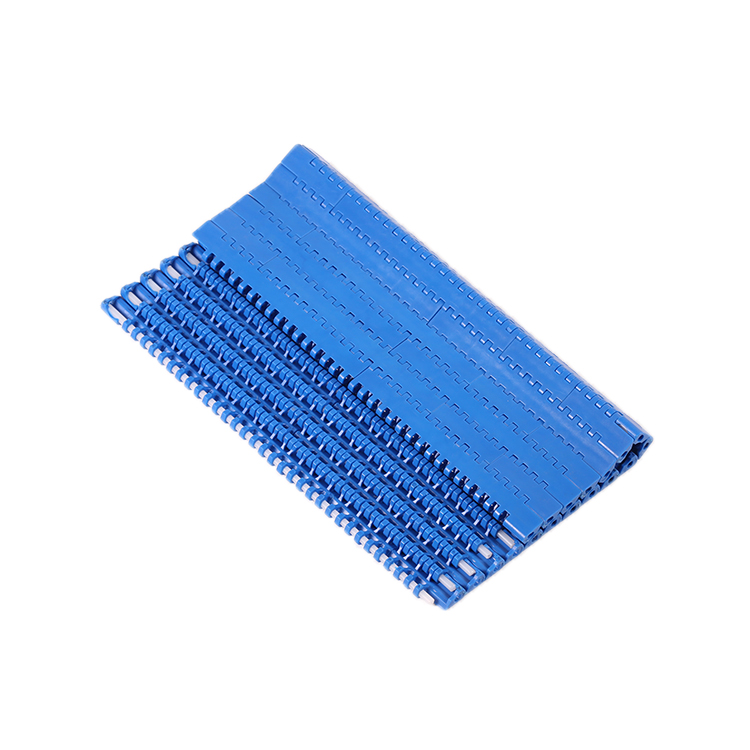

PVC and plastic belts: Ideal for the food and pharmaceutical industries due to their ease of cleaning and resistance to bacteria.

Metal belts: Used in high-temperature environments.

Serrated and inclined belts: For transporting materials across different levels.

The choice of type depends on the nature of the product, the length of the track, and the operating speed, and Machine Belt offers solutions tailored to your needs.